Category: Project Boat

AND SO IT BEGINS

John Willis leads the Spooled project boat team in restoring a legendary Stabicraft 490

It took a while for Stabicraft to gain acceptance in Australia. These gutsy Kiwi armour-plated warriors were undoubtedly strong and built with a safety factor far exceeding any other production alloy boat with their fully compartmentalised pontoon flotation. The ride was pretty good and stability excellent. The internal layouts were reasonably good for the time and the dealerships were strong. So, what was the problem? They were butt ugly, that’s what!

Stabicraft were first developed in Invercargill, NZ, in 1987 for commercial abalone (paua) divers, and they soon built a great reputation in hard working environments where beach launching is the norm. The hull and deck designs have progressed throughout the years – Generation 1 and 2 – with their first fully recreationally-based model, the 550XC, developed in 1996. Growth exceeded the production facility, hence Stabicraft built a second factory and service centre in 2008. At the same time they developed external markets in Alaska amongst others, and produced the Generation 3 hulls.

In Australia, Victoria-based dealership MY Marine Dromana took on the Stabicraft challenge with gusto. You’ve got to give them great credit. I mean, how many times can you hear those words, “great boat mate, but it’s an ugly duckling” and maintain strong enthusiasm? Yet, with their faith in the Stabicraft ideals, plus a whole bunch of downright tenacity, MY’s Michael and Theo Rozakis introduced the range to Australian boating that would go on to become a leading product in a very competitive field.

Australian commercial operators saw the benefits of safety and stability immediately, while the recreational sector chose to argue the construction theory on early on-line chat rooms such as Fishnet. Slowly, but surely, the coin dropped, with many hardened sea-dogs finally accepting the brand.

Stabicraft worked hard at it, too! It’s fair to say there has been strong development throughout the years, refining the ride, design, aesthetics and finish to their current industry-leading levels. The hulls developed their current “Arrow Pontoons” and “Game Chaser” transoms in 2011, with the outward appeal, paint jobs, cabin shapes and decals transforming from the ugly stepsister to nautical nymphs. Complementing this, internal fit-outs now offer attractive creature comforts combined with solid workability. By 2016 Stabicraft were producing around 600 boats annually, employing 70 skilled peopled and servicing a large dealership base in NZ, Australia, USA, Canada and New Caledonia.

Back in the early years of the Stabicraft/MY Marine relationship, Michael and Theo got their father, a very keen local angler, into possibly the ugliest of all Stabicraft – a 490 cuddy cabin. In fact, it was so ugly that when they went to display it at the boat show, the guy on the gate said, “This is the boat show mate. The freak show at the circus is up the road!”

But we fisho’s are used to looking through surface layers to the depth below. This little craft was actually built with some very worthy credentials, providing a much-loved workhorse that has led an all-out assault on the indigenous squid, whiting and snapper population of Port Phillip and Western Port for the last 19 years.

Our team at Spooled was looking for a project at the same time as the 490 eventually hit the market. The original Mercury 60HP 4-stroke “Big Foot” was replaced by a later model Yamaha 60HP, but we knew we’d have to transform the package considerably if we ever wanted to catch the local fish from her, as the current population has been solely depleted by her continual presence. What fish are left slink off into hiding on her morbid approach. It’s a bit like the eerie presence of Voldemort’s dementors really!

So, the challenge began, not only to fully restore this battle-weary weapon of fish destruction, but to repair some corrosion, convert the inefficient internals, update the fittings, electronics and accessories, and perhaps the outboard as well. The biggest challenge, however, is to convert butt ugly to glamor, and we needed some skilled alloy surgeons and artisans for the task!

OZSEA TO THE RESCUE

The boys at Ozsea Plate Boats in Seaford, Victoria, aren’t new to building tough custom boats, and they’re certainly not scared of aluminium repairs. Their long boat building experience includes extensive construction of commercial and charter vessels for ex Melbourne-based Pro Marine, where they worked hand in hand with respected marine architect Denis Pratt, as well as a number of years with recreational leader, Bar Crusher Boats.

Ozsea’s Brendon and Barry are great blokes who could also see the potential in the little Stabicraft 490 Cuddy and, thankfully, volunteered their services for the rebuild and repair.

Quick as a flash we stripped the little duckling down to a bare shell and as we did, we found more and more misdemeanours, mainly due to non-conducive metals and fittings creating pockets of corrosion. Most people commonly call aluminium corrosion “electrolysis”, but in fact that is part of the process used to create aluminium, not eat it!

So, our project timing was terrific for this little warrior. The hull was completely bead blasted, and we found that damage wasn’t too widespread. With the aluminium completely bare of paint and corrosion, we could truly start the project!

The wish list on the hull includes:

- Repair all corrosion to start with a fresh, clean hull

- Remove the weak and ugly old windscreen and replace with a tough wavebreaker

- Rework the cabin storage to something more practical, improving storage, but still allowing bow access through the hatch

- Remodel the seat supports

- Eliminate the portable fuel tank and fit a permanent aluminium replacement

- Replace all of the rod holders and fittings

- Replace the bait board and cutting table

- Remodel the anchor well for new Lone Star drum winch and bow sprit

- Remodel the gunwale

- Paint with non-reactive surface suitable for a wrap

The wish list for accessories and fittings includes:

- Hydraulic steering

- Water separating fuel filter

- New electronics package

- New flooring and non-skid trim

- New fishing rod holders and accessories

- New fittings throughout

- New canopies

- Whilst the current units are still serviceable and in good condition, perhaps a new trailer and outboard

So, stay tuned for the progress, along with hints and videos along the way! Then we’ll take it fishing…

Magazine

Spooled Story

Get Spooled

Contact

- editor@spooledmagazine.com.au

TIME FOR A FACELIFT

The transformation of a tired and very well used inshore fishing rig continues.

Boating and fishing trends have changed considerably in the decades since our little Stabicraft armour plated hero was crafted. Fisho’s now demand highly refined layouts to match their style, tackle, electronics and accessories. Hence our wish list for the little Stabi 490 was formulated after a good round of brainstorming with Barry and Brendan at the Ozsea Boats factory in Seaford, Victoria.

If you remember where we left off last issue, the hull was completely sand blasted, revealing cracks, craters and crevices, as well as removing the oxidation around the corrosion and the original paint. We found that damage wasn’t too widespread, and with the hull completely stripped, we could truly get some indication of its condition. Ozsea’s Brendan Tilders said, “If you don’t do it all properly from the start by bringing it all back to a clean surface, you are totally wasting your time!”

WISH LIST

Our wish list on the hull included:

* Repairing all corrosion to start with a fresh, clean hull

* Removing the weak and ugly old windscreen and replacing with a tough wavebreaker

* Reworking the cabin storage to something more practical, improving storage, but still allowing bow access through the hatch

* Remodelling the seat supports

* Eliminating the portable fuel tank and fitting a permanent aluminium replacement with deck fill

* Replacing all of the rod holders and fittings

* Replacing the bait board and cutting table

* Remodelling the anchor well for new Lone Star drum winch and bow sprit

* Remodelling the gunwale

* Fitting a new rear ladder

* Fitting new transducer brackets

* Painting with non-reactive surface suitable for a wrap

Thankfully, the amount of corrosion was minimal and mainly centered around non-conducive metals where bolts, screws and fixings had come in contact with each other without suitable sealant. These small pitted areas were quite easy to repair with the MIG welder, as the plate alloy construction is thicker than the lighter pressed aluminium boats, enabling the welder to get some real penetration without burning through thin sheets.

We have seen incredible popularity in replacing old and often daggy and crazed windscreens with solid wavebreakers to improve protection. And it’s hard to imagine a daggier windscreen than the original on the Stabicraft. Hence, the Ozsea boys set about forming a new alloy wavebreaker that not only gives improved protection to the driver and passenger, it’s a solid shell, should we take a big breaker crossing a bar, and makes the dashboard space below more protected for mounting electronics.

The original cabin was a disaster. It had a single plywood sheet covering a shallow cavity that went full width and length to the bow. Not only was the storage height underneath impractical, it was impossible to get into with other items on top. Any boxes and bags up top were not well retained and would go flying around in choppy or rough conditions. We removed the plywood entirely, leaving the raised alloy retainer and forming a workable space to fit a large twin door Icey Tek icebox. In our opinion you simply can’t go to sea without a good icebox, and they definitely don’t get any better than Icey Tek. They keep ice cold for days on end, even in blistering heat, and serve to keep the bait, food and refreshments cool. The Icey Tek also doubles up as a kill tank for your catch. You simply shouldn’t kill a fish for the table if you’re not going to treat it well from the time of capture by dispatching it quickly without stress and cooling the flesh ASAP.

The twin doors on this sturdy, insulated polyethylene icebox make access from either side a breeze, and its tough construction means it can be dragged in and out of the boat easily, doubling up for other adventures. There’s plenty of storage room left up in the bow for tackle bags and the like, and we suspect we may end up permanently mounting a second battery box up front dedicated to the winch and accessories; but more on the electricals to come. We can still get through the large cabin hatch if we need to, but with a new Lone Star winch planned for the bow, chances are we won’t ever have to use it.

The driver and passenger seat supports were another item of contention. They were certainly very strong, but had limited storage capability. Our brainstorming session developed a pair of hinged hoppers that now provide ideal, protected storage for flares, torch, tackle and assorted nick knacks that we fisho’s like to gather. We have also decided that, due to the limited size of the boat, we are not going to fit bulky upholstered seats. Instead, we are simply fitting padded cushions to the tops of the seat boxes. They can be made detachable for cleaning and dry storage, reducing wear and the risk of a wet bum after rain and dew. This is certainly a stand-up style of boat to drive anyhow, particularly now with the solid wavebeaker.

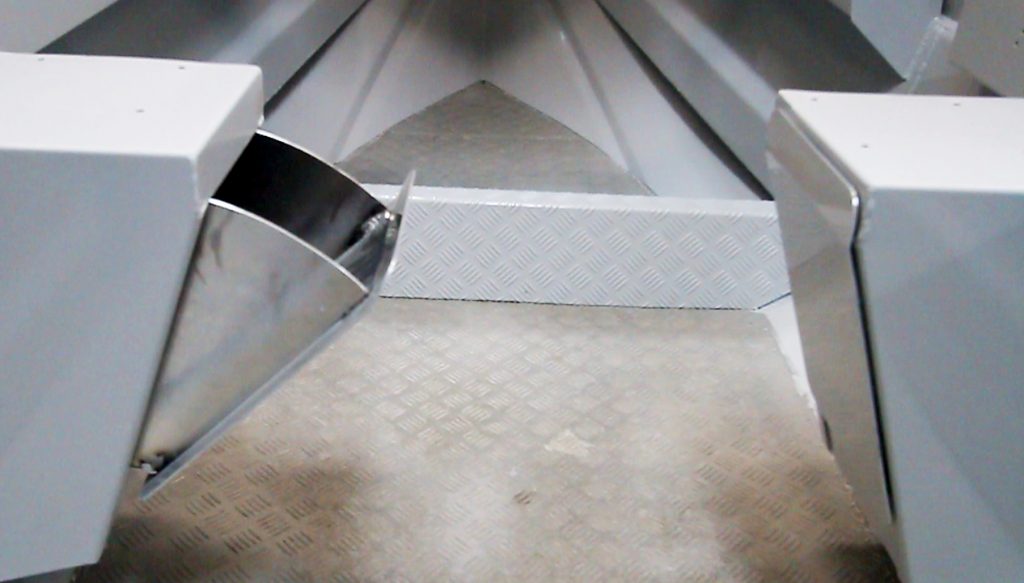

The original transom layout was a disaster. It had portable fuel tanks drifting around, with an open battery and bilge wiring everywhere. We decided an aluminium custom made fuel tank would neaten the entire area, be much safer, more practical and wouldn’t intrude into the deck area. The Ozsea boys not only built a ripper alloy fuel tank, it now has deck fill and breathers outside the hull into the transom. It’s around 50 litres in capacity, giving terrific range with the thrifty little 60HP Yamaha 4-stroke. For really long sojourns we can still carry a portable fuel tank in the bow. You simply can’t have a fixed fuel tank without a decent water-separating fuel filter either.

We made sure that the fuel tank was mounted on a raised platform for a number of reasons. Firstly, this is a self-draining boat so we maintained unobstructed deck flow right through to the scuppers. It also allows easy washing and cleaning of the whole area, reducing the opportunity for rubbish to gather causing corrosion.

The battery now has a suitable platform for secure mounting in an enclosed box, and there is still room for a large bilge pump and float switch, plus the excess wiring has been neatened considerably. Out back, the function of the craft has been lifted dramatically with a fold-down ladder for easy boarding, both on and off the water. The Ozsea boys even welded on a pair of transducer brackets covering the old corroded mounting holes, which this means there will be no screws piercing the transom except the engine mounting bolts.

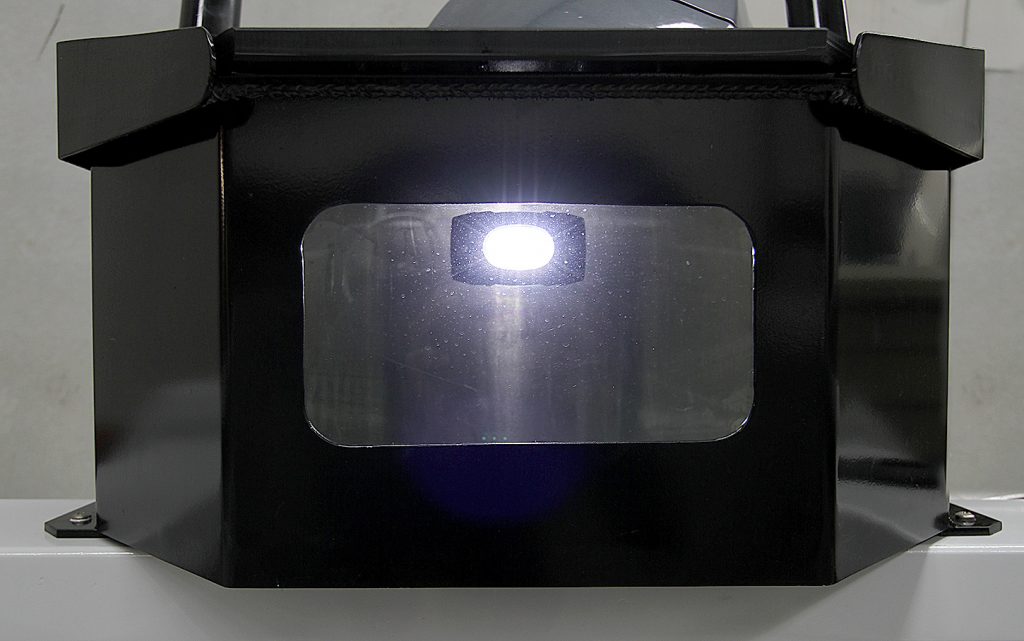

You just can’t have a serious fishing boat without a good cutting board, and the Ozsea boys have manufactured us a ripper unit. It is actually modelled a bit off the modern combination unit that Stabicraft now incorporates into their “Game Chaser” transom layout, with the bait board and rod holders on top and a fully plumbed live bait tank beneath, complete with viewing window. It hasn’t been properly located as yet until we refit the engine to allow for full engine tilt.

PAINT ME UP!

We checked the engineering clearances for a new Lone Star electric anchor winch and made sure we could refit the rod holders and select fittings. Then it was off to the spray shop, where cleanliness is next to Godliness!

The entire rig was vacuumed, air hosed and thoroughly degreased with Ali Brite (an acidic wash), ensuring complete cleanliness. Any paint left in crevices, welds or similar must be removed, as the residual acid will cause a reaction in the future. You must ensure that that the entire boat is thoroughly rinsed after the acid wash and avoid any contact with any other surface, including glass. Strict safety and drainage precautions and full protective equipment must be utilised.

Once the boys were sure of the cleanliness of the entire rig, it was time for the spray job that, of course, begins with a 2-pack epoxy primer, in this case from PPG. The checker plate floor and hull beneath the chines were to remain unpainted, and hence they were masked and covered to avoid overspray. It is vital to use alloy-compatible paint or it will create a huge amount of corrosion. I have actually seen hulls destroyed from using the old paints with lead, chrome and high nickel contents, although there are not many of our current paints that still use such components.

The Ozsea boys spray two coats of epoxy primer, rubbing back between the two applications, forming a filler for any minor imperfections. Once satisfied with the prepared and primed surfaces, they use and recommend PPG 625 2-pack polyurethane sprayed lightly, with many coats to final finish. Ozsea’s Barry said, “Just be patient and use many light coats to slowly build the final finish. Leave enough drying time between the coats to become tacky so as to attain a high build and smooth finish without runs.”

We only did a basic white spray job, as we will be applying a custom wrap from our friends at Signarama. However, it does have some black trims for the rocket launcher, dash and wavebreaker. Once she cured, it was time to load her back on the trailer and head over to my place for the engine, hatch and component refit!

The new componentry, modifications and spray job have turned “Butt Ugly” into “Awesome”, thanks to the engineering prowess, patience and imagination from Barry and Brendan at Ozsea! Thanks fella’s, and now it’s off to the next exciting stage.

Stay tuned for the progress, along with more hints and video’s along the way. Then we’ll take it fishing!

Magazine

Spooled Story

Get Spooled

Contact

- editor@spooledmagazine.com.au

BUTT UGLY BECOMING A BEAUTY

Well sort of…

Like most early Stabicraft, our Spooled project boat certainly started life as butt ugly or even affectionately, Fugly! Yet the strip down, repairs, modifications and a new spray job from the boys at Ozsea Boats in Seaford certainly started the transformation. I don’t think she’ll ever morph into a beautiful swan, but certainly now has the potential to ‘phoenix’ into an impressive aquatic assault vessel.

The new black wave breaker certainly gave this little craft an alter ego. Let’s face it, she’s turning from a puce pussy into an armour plated Trojan. With our modifications she has gained an incredible amount of serviceable function that will now gain respect instead of ridicule.

We waved goodbye to Barry and Brendon at Ozsea after they sand blasted, repaired any misdemeanours and corrosion, fabricated the wave breaker as well as a new inbuilt fuel tank, transformed the seat storage and made the small cuddly storage functional and trailered he back to my place for the engine fit and bolt down.

Our old mate John Fay at Icey Tek solved the icebox, bait, refreshments and fish storage problem with one of his ripper 70 Litre roto-moulded boxes with dual lids for easy access. We really like the fact that it’s not only removable at the end of a watery session, but it runs east-west across the cuddy and is secured by the original cross frame, at the same time creating quite some forward secure storage space. I have used these Icey Tek ice boxes in two other project boats and find them exceptionally tough, attractive, functional and will keep your precious cargo cold for days on end.

It seems ice box construction is a little more high tech than most of us consider, with the hinges and fittings made using 316 stainless steel, premium thermoplastic/elastic catches, dual bungs (very handy for draining from either end), high quality roto-moulded polyethylene outer skins, plenty of internal insulation and smooth food-grade internal liners. John explained that the smooth internal liners are essential, as they are impervious to contaminants and hence will not hold smells and restrict bacteria growth. There are optional cushions that make terrific seats in portable excursions and, with the prevalence of large pelagics currently available in our home waters, we have also ordered an insulated fish bag to quickly cool a big’n.

The new alloy fuel tank under the transom is around 50 litre capacity, which is more than adequate for many sea miles. Yet we are still toying with an added bow tank, and now there’s room, but let’s see how she rides first. At worst we can now easily carry portable tanks for extended sojourns far from civilisation. The icebox has created a terrific barrier in the cabin, forming a deep cavity suitable for carrying tackle boxes, safety equipment, lure rolls and the multitude of other gear we tend to gather for serious fishing trips.

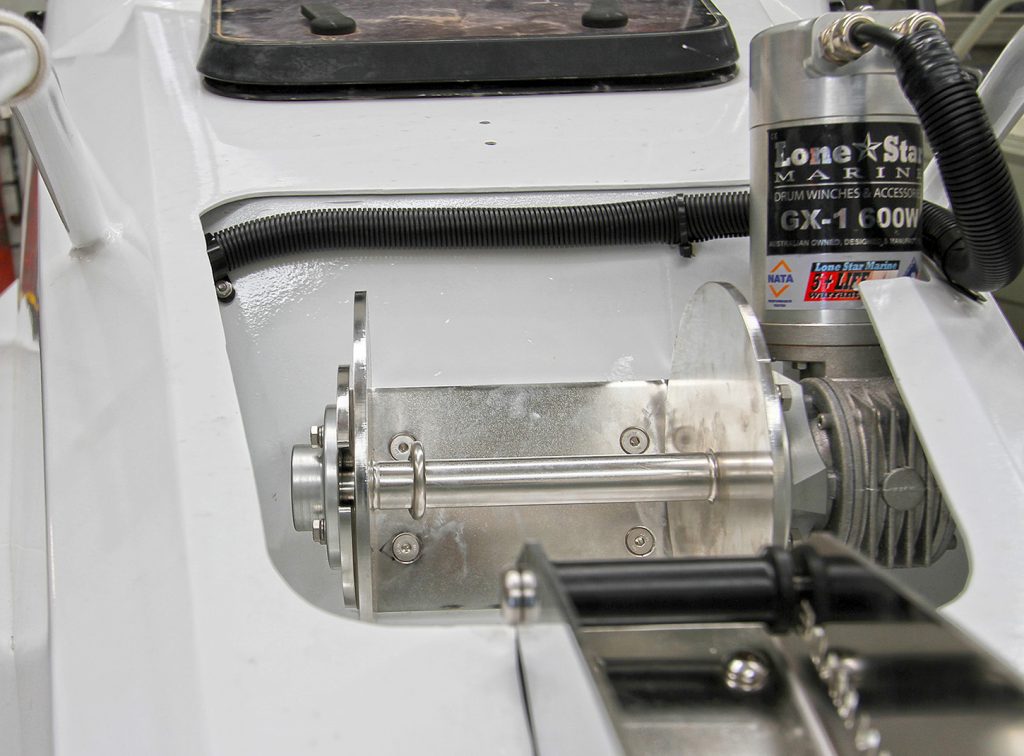

Bow access through the front hatch will now be restricted, but still possible; however, we won’t need it because the infamous Malki Ary from Lone Star will be providing a new GX1 drum winch with all the ground tackle and accessories, including a stainless steel bow fitting. There is no question in my mind who won the “winch wars” of the past, and who also comes with a great reputation for customer service. These Lone Star winches are tried, proven and are true blue Australian-made. That’s good enough for us!

Meanwhile, back at my place I got the job of sorting out the shemozzle of nuts, bolts, looms, control cables and assorted fittings. I must have removed 50m of useless wiring, most of which wasn’t tinned cable nor colour coded, and mainly corroded with rotten plastic outers. Corrosion will simply travel throughout non-tinned cable, causing potentially dangerous failures, and at the least major frustration.

My wonderful little mate and “Spooled” owner Rob, bless his little heart, had done his best when removing the engine, gauges and components, but had disconnected the engine by disassembling the hand set controls instead at the engine. Wrong move, Rob! It’s just lucky you weren’t around to cop the wrath of the Bear while I sorted out that little mess!

At the other end, the engine needed to be refitted and sealed, but I no longer have my big workshop and gantry for lifting. So how was I to separate the boat and engine, securely take control of a 113 kg outboard and refit the mounting bolts with sealant – all alone? The answer was to back the boat under the carport, making sure the engine was in line with a strong cross member in the truss. I lowered the tilt by releasing the relief valve on the side of the trunk and nipped it back up so it was locked in the vertical position.

Next I positioned the jockey wheel so that I could securely lift and lower the bow on the axle axis until the skeg of the engine just touched the ground, taking the weight. I had a top rope tensioned from the engine lift points keeping it upright enabling me to take full control when the mounting bolts were released. I virtually removed the boat from the engine, not the engine from the boat, sealed the whole unit with neutral cure silicone and replaced the bolts individually. Some will use Sikaflex or similar sealants, but let me tell you, you don’t ever want to try to change engines if you do!

You need to be very aware of your steering arm at this point, especially if you are using standard non-feedback cable, as in most cases the steering arm needs to be installed while the engine is free swinging. It wasn’t so important with Fugly, as we were replacing the hydraulic steering that came with the boat, but you still need to ensure that you fit all of the necessary links before bolting the engine back on permanently.

The gauges were refitted, switches mounted, wave breaker securely bolted and the steering reassembled, with the wiring, shift and throttle cables all pulled through the tight channel along the side pockets. Always make sure that you leave a pull-through in the channel for further accessory cables. In my case I use a plastic strip from yellow tongue flooring.

I am a boat builder, not an electrician; in fact, I hate fitting electrical wiring. After all these years I now have a basic understanding of electrical circuitry, but I will always pass the job over to the experts rather than botch it up myself.

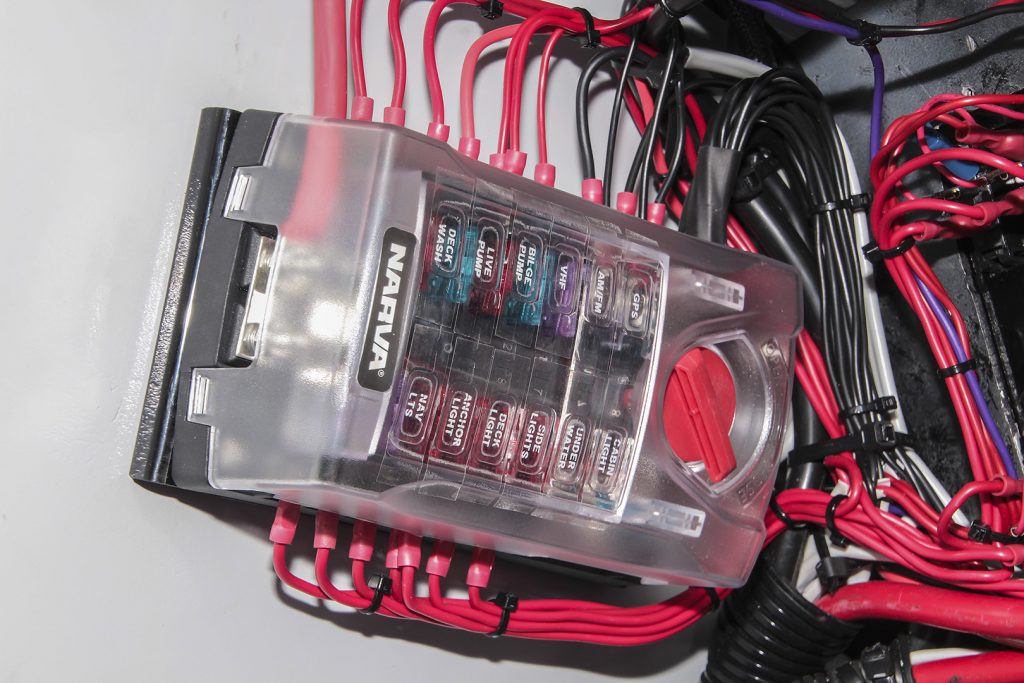

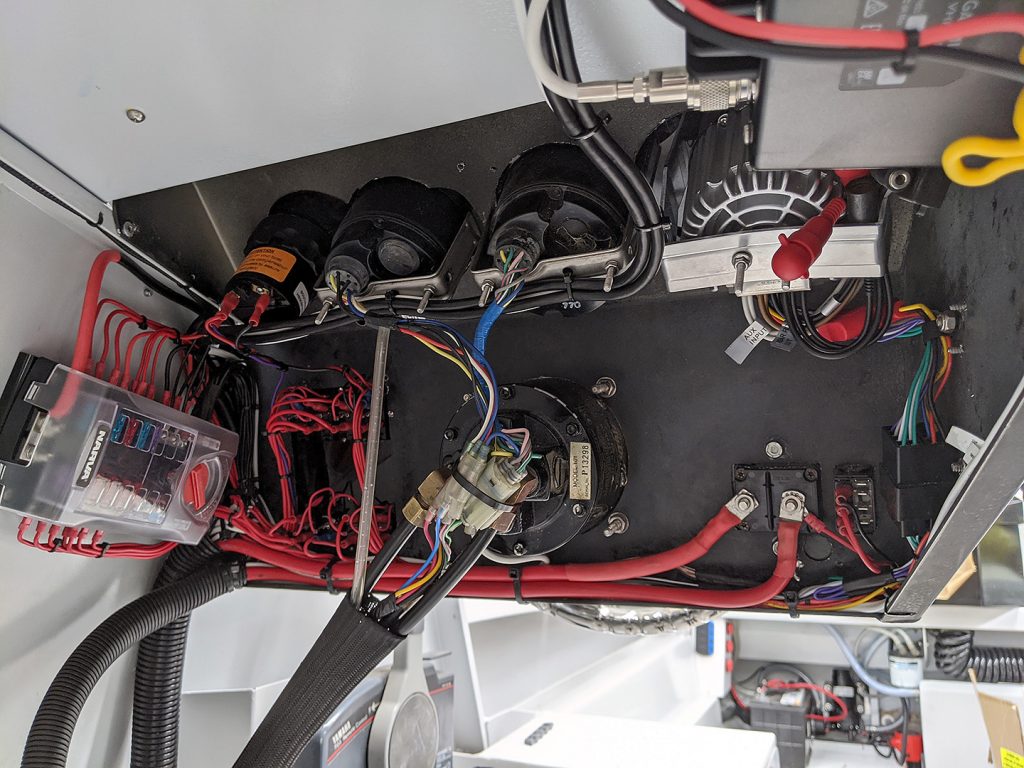

This is where another old mate and genius ex Australian Navy aircraft electrical/electronic engineer, not mention former super yacht industry whip Michael Fitzallen from Nautek Marine, entered the project. The team at Nautek are the go-to guys for getting a proper job done. There is almost nothing more dangerous in an aluminium boat than bad wiring, not only with obvious shorting, but invisible power leakage that will cause electrical corrosion throughout. You would be amazed at just how quickly this form of corrosion (often loosely and incorrectly termed electrolysis) will turn aluminium to chalky powder!

It is vitally important to use premium connectors, tinned wiring, tidy colour coded looms and high quality waterproof switchgear in any boat, but most certainly in small alloy boats with a high possibility of salt water soakings. The salt itself is a good conductor and vicious corrosive, so a professional wiring job is essential.

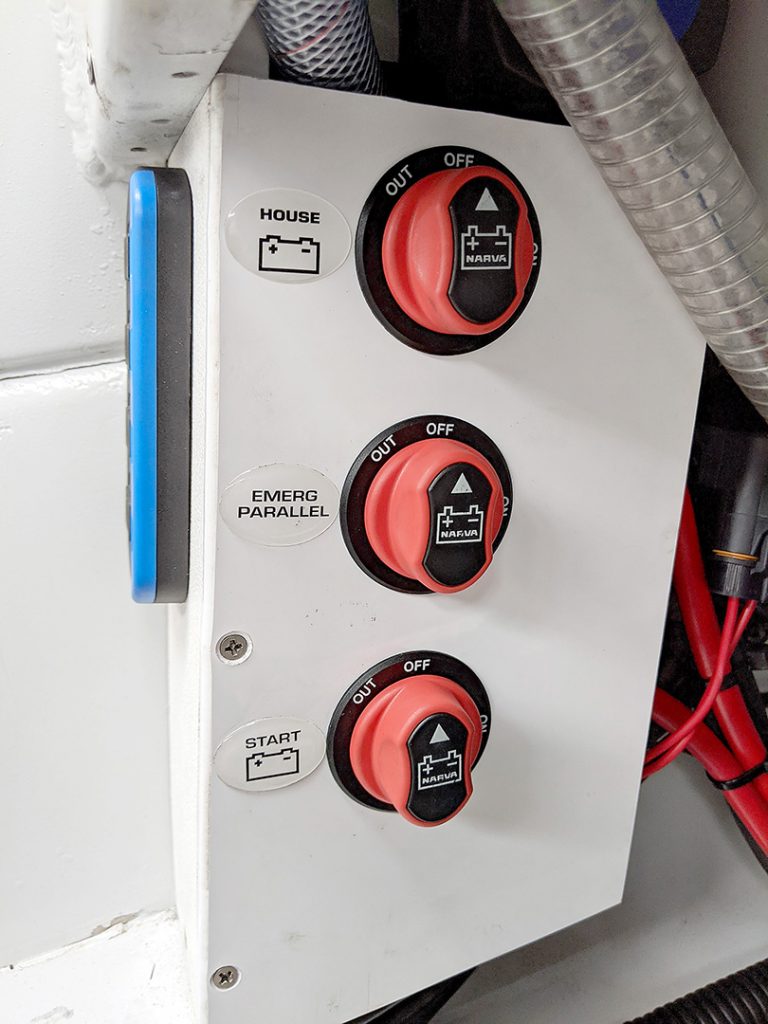

Michael strongly recommends creating a wiring plan for the loom, ensuring sufficient power to all of the electronics, and we have plenty to consider. The winch is the primary accessory with by far the highest power drain, and hence has its own circuit run directly from the “house” battery in our twin battery setup. We are also utilising a Narva VSR (Voltage Sensitive Relay) Battery management system to ensure that the engine starting is never run down by the raft of electronics. Most of our lighting and electronics have evolved to lower power draw due to modern LED and LCD technology, but it still all adds up.

Garmin is always keen to put their money where its mouth is and, as such, has supplied us with a EchoMap UHD 95SV Model touch screen colour sounder/GPS multi-function unit and Garmin VHF 115 radio . We couldn’t be more pleased with their contribution, especially since the GPS/plotter is one of the first to combine both Garmin charts and Navionics after Garmin recently acquired the brand and its intellectual property. More on all that later, but we have planned for uninterrupted power in the installation. Making a new gadget like the Garmin sit perfectly on the dash with a customer “fitted-from-factory-look” took a bit of crazy trigonometry planning by the Nautek team. It looks suberb in a practical location to use this latest tech, and more so, easily find the fish.

We just love having great sound to accentuate our fishing excursions, and Audioxtra have joined the party with a terrific Axis sound system with a MA1802 watertight marine AM/FM radio, Bluetooth and multimedia head unit combined with MA600B ultra slimline marine speaker system. These speakers feature an IP65 weatherproof rating to rock the fish straight out of the water!

Nautek fitted three switch panels, two in-dash and the other on the starboard side in the back coaming. The dashboard switch panel operates all the essentials, such as navigation and work lights, coaming lights etc, and the stern-mounted panel is for the array of accessories. These include the live bit tank pump, deck wash and internal light, plus quite a few added bonuses supplied by the premium electrical wizardry from NARVA.

We have the twin battery BMS, navigation and overhead work lights with twin 5W LED’s, blue 5W underwater lights (rated to 50,000 hours lifespan), high output waterproof LED strip lights, and even a complete new ‘plug and play’ boat trailer wiring kit with waterproof connectors so there’s no splicing or joining immersed wires. The best thing is the confidence of knowing we have the very best in marine electrical accessories from NARVA, teamed with professional and experienced installation from Nautek.

Nautek also connected the fuel tank gauges fitted by Ozsea, a spunky new sports steering wheel and provided a host of sensible layout ideas and alternatives. Yet again, it’s all in experienced planning!

So it’s onwards and upwards for “Fugly” and now we are hanging out to finish the project and go fishin’!

Magazine

Spooled Story

Get Spooled

Contact

- editor@spooledmagazine.com.au

FUGLY GETS SOME BLING

Spooled’s project boat is nearing completion, and it’s looking pretty damn good!

The tale of Fugly continues onwards and upwards. As we wheeled her out of Nautek Marine she was almost fit for purpose, but even with the spray job, including the black wavebreaker from the boys at Ozsea Plate Boats and a complete rewire and refit from our mates at Nautek Marine, she was still butt ugly. Let’s face it, Fugly needed all the help she could get with her homely aesthetics that only a mother, or a welder, could love.

There’s no hiding these blemishes with stage lights and makeup, and we certainly didn’t want to have to chew our arms off waking up to Fugly for early morning fishing trips in her rather undesirable condition. She was far past a simple bedroom makeover, so it was off to the experts to make her not only liveable and functional, but to transform her to be appealing and alluring.

They say money can’t buy happiness, but it can definitely buy bling! And nothing dresses up a craft like some fashionable stainless steel jewellery, accessories and a new dress-up. I’m talking, of course, of custom stainless steel work and a new set of canopies, so it was over to our mates at Steve’s Custom Welding and Barca Covers and Canvas in Melbourne’s eastern suburbs.

Dressing a boat simply must have a programmed approach with a plan that’s clearly understood between the contractors. The stainless engineers need to work with the canopy makers and upholsterers to ensure a suitable framework for differing styles of canopies. In this case, our original rocket launcher was adapted with new fittings for the navigation and deck lighting, taking care that it was suitable for attaching the bows and fittings for a complete bimini and set of clears. Steve also converted the original mounts on the rocket launcher to make the tilting mechanism much easier.

Steve and Rick work together often on projects and hence there was nothing left to chance. Both understand the requirements of varying fisho’s, and the overall need for adaptability for those who will be fishing in extremes of climate – from stinking hot to freezing cold, but also in many varied target species, from fresh to salt water, lakes, rivers, bays, estuaries and offshore. Hence, layouts and accessories need to be flexible.

Ozsea had already manufactured that ripper bait board with its live bait tank, storage and a couple of trolling rod holders. However, we do loads of bait fishing down south for the likes of snapper, whiting, bream, gummies etc and hence needed a set of strike-out style rod racks that could hold up to four rods on either side of the boat and at near horizontal angles to allow the rod blanks to perform when that strike finally occurs.

They have been made easily detachable, with rod holder insert one end and a thumb-screw fitting to the bait board. If we change from bait fishing to trolling during the day, it’s an easy conversion. I must say that it is a pleasure to see the quality of welding and overall workmanship displayed by Steve’s Custom Welding, producing a very professional high gloss custom product that assists the bling.

Steve also worked with Nautek to design and fabricate the dash-top mounting bracket for the Garmin multi-function electronics that has allowed exceptional protection and security, as well as line of sight vision. It has expanded the limited dashboard availability utilising the protection of the wavebreaker.

Steve’s last assignment was to fit our new Boatcatch to the existing Dunbier trailer, giving it single handed launch and retrieve operation. There are a great many similar products on the market,, but none with the absolute strength, simplicity and reliability of Boatcatch. The spring loaded locking mechanism is virtually failsafe and being constructed of 100 per cent marine grade stainless steel (316), this incredibly robust product comes with a lifetime warranty.

With only three moving parts, it requires little maintenance and, being highly polished, Boatcatch is a very attractive accessory to any trailer boat, adding to the bling. There’s no doubt that Boatcatch not only makes boating easier, but drastically improves safety for all at the boat ramp.

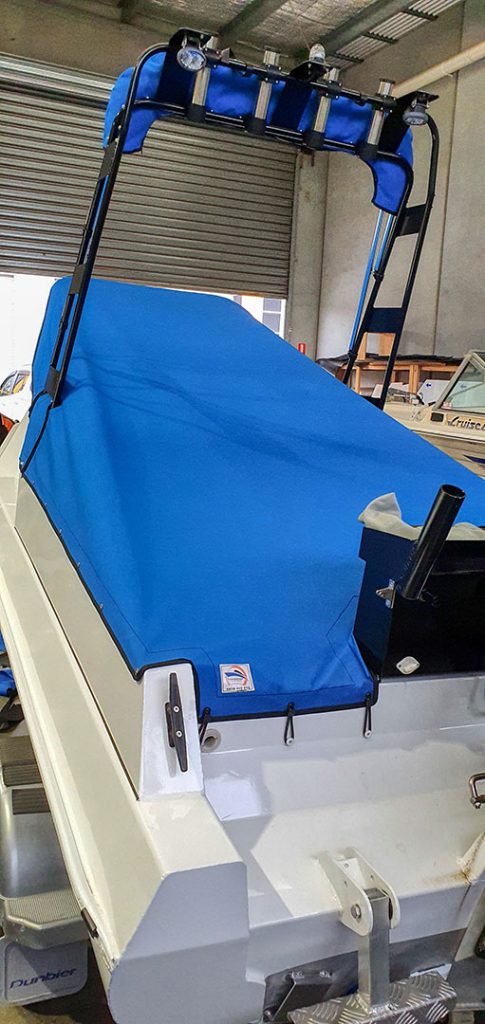

UNDERCOVER EXPERTS

Next it was over to Rick at Barca Covers for a complete Bimini and full set of clears, upholstery and travel/storage covers. Rick is a very likeable fellow who showed a high level of skill in the job. His work has absolutely transformed Fugly to help evolve her growing attraction.

There have been some terrific advances in canopy design, construction and materials, and nowadays a good Bimini cover with detachable front and side clears allows you to adapt to all conditions, hot and cold.

Modern materials simply last longer and look sharper than previous offerings. The soft-top Bimini material is Sattler Excel 290gsm 100 per cent solution-dyed acrylic with a TexGuard coating, allowing outstanding water, dirt and fungal repellence, 90-100 per cent shower protection, strong UV protection and a 15-year warranty. The clears also withstand far greater abuse and UV exposure, however they all still need to be treated carefully.

To care for them you should wash them with a mild detergent only and never pressure wash, as it removes the coatings. After cleaning, it’s recommended to maintain your clears with an approved cleaner for a longer lifespan.

It’s also worth noting that you should never fold your clears for storage, nor put them away wet, as they can trap the moisture, causing damaging mould. The chunky size 10 zips slide easily and even the method of manufacturing has seen advances, including overlapping and Velcro flaps to minimise water ingress.

Attaching the clears to the return lip of the wavebreaker has always presented a challenge, but Rick fixed the problem with extensions to the detachable clear section that folds under the return and secured by stainless press studs. This will ensure that the water should never flood onto the dashboard, even when punching through a nasty head sea.

The front clear section is also getting its own zip-up window to make it easy for the driver to see at night. It’s amazing how restrictive the reflections, even on clear vinyl, can be obscuring your view, especially when salt water has crystalised.

Travelling long distances with the front clears up will cause enormous added drag and draw greatly on fuel efficiency, so we decided on a full travel cover from windscreen to rear. The clears are easily removed and the Bimini folds back to the rocket launcher with its own storage bag, making the travel cover easy to fit. It encloses the whole cockpit for secure storage and weather resistance.

I must say I was a little taken back with the choice of canvas colour! I honestly expected it to be black matching the theme of the wavebreaker and white hull. My first impression of the finished item was WOW – it’s BLUE! Like so many new fashions, it took a little while to fathom the colour concept, however when I looked at the matching internals, old Fugly took on an entirely new character and dimension. It was almost enough to put a horn on a jellyfish!!!

Rick has done an excellent job with the black graphite-style upholstery with its vivid blue embroidered inserts and trimmed edges that also match the blue offsets on the switch panels, front and rear. We had decided on simple, but thickly padded seat cushions, as there really isn’t enough room for a pair of large bucket seats, and hey, it’s a fishing boat, not a maiden’s parlor!

We have also ordered a clip-in rear curtain to enclose all of the fuel tank, plumbing and electricals under the transom that will have the Spooled logo embroidered to match the seats. To say we were impressed with the quality and function is an understatement, but more so the Bimini and trim really altered the overall presentation from a daggy old fishing boat to a very impressive and amazingly attractive sportfishing weapon!

FEEL THE POWER

Oils ain’t oils and batteries ain’t batteries! Australian owned Club Assist has forged worldwide partnerships in the automotive industry, including in excess of 66 million members across the world. They partner with motoring clubs, providing operations, distribution facilities and mobile battery service programs including marine power.

Their products and services provide the finest automotive batteries and mobile roadside support tools, including state-of-the-art testing and diagnostic equipment, and tools related to battery replacement. Their service partners include our local RACV plus the NRMA, RACWA, and RAC New Zealand.

Club Assist migrated across the world in 2001 to partner with the American Automobile Association (AAA) in the United States, and the Canadian Automobile Association (CAA). We were very thankful to have partnered with Club Assist, who provided a pair of their own Atomic Batteries to power our little Stabicraft, and with the amount of new electronics fitted by Nautek Marine, we will need them to maintain tip top power supply.

Fugly now has two Atomic lead acid 7601 “dual-purpose” marine batteries. (720 CCA 85Ah 160 RC calcium lead acid) Dual purpose batteries are designed to put out optimum cranking power for starting the engine with the good amount of deep cycle AH (Ampere Hour -the measurement of supply circuit discharge capacity), keeping all the accessories and gadgets on the boat powered up long after the engine is switched off.

Atomic batteries are constructed to handle harsh, high impact marine environments and require extremely low maintenance, as their strong inner construction, partnered with a rugged, fully sealed outer casing, means ultimately safety, as they cannot spill and never need to be topped up. All Atomic battery products meet ISO9001 quality systems and ISO14001 environment system accreditation.

Atomic marine batteries are the battery of choice for reliability, durability and high-performance with premium Club Assist service to match. With close to 30 years as Australia’s leading battery experts, Club Assist expertise covers just about everything mechanical. And so it seems that all batteries, nor their maintenance services, are created equal.

So now to complete the bling, it’s over to our great mates at Form A Sign for a complete individualised wrap and some ripper U-Dek flooring. I think we’re going to need a new name for Fugly!

Magazine

Spooled Story

Get Spooled

Contact

- editor@spooledmagazine.com.au